Rebranding and Reinvention in Manufacturing

The transformation of B&J Industries into Future Form Manufacturing marks a turning point in the manufacturing sector. This rebrand isn’t just a new name—it signals a strategic pivot toward expanded capacity, modernized processes, and a vision for the future. The change reflects an effort to get into new markets while reinforcing the company’s long-standing commitment to quality engineering. Many in the industry are taking a closer look at this shift, recognizing that rebranding initiatives like this one carry both challenges and inspiring opportunities.

At its core, the decision to rebrand is driven by a need to find your way through a competitive and sometimes intimidating market environment. Companies today need to steer through numerous twists and turns that arise from global supply chain issues, rapid technological advances, and evolving customer expectations. As Future Form Manufacturing embarks on this new journey, the rebrand offers insight into how businesses can adapt and progress while balancing modern technologies with traditional manufacturing expertise.

Expanding Production Capacity for a Changing Market

The announcement of a significant facility expansion in Sparks, Nevada, is set to triple Future Form Manufacturing’s daily production output. By leasing an additional 30,000 square feet adjacent to their existing headquarters—bringing total floor space close to 100,000 square feet—and with another 90,000-plus square feet under construction, the company is effectively preparing itself to meet skyrocketing demand.

This expansive growth initiative is essential for meeting the unique needs of major sectors such as data centers, medical, defense, energy, and transportation. As future markets evolve, retooling production capacities isn’t just smart—it’s a must-have strategy for any business that plans to thrive under changing economic conditions.

Facility Expansion Details and Capabilities

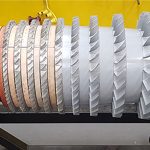

Future Form Manufacturing is investing heavily in modernizing its production environment. The facility now boasts an impressive range of capabilities, including:

- Large-scale CNC machining

- Sheet metal fabrication

- Tube laser cutting

- Precision welding

- Powder coating for enhanced durability

- Comprehensive assembly processes

- Advanced engineering support

These advancements are designed to streamline the quote-to-cut process and offer quicker turnaround times for customers. In addition, the integration of these diverse processes in one facility means that the company can provide holistic manufacturing solutions, aligning with modern automotive, industrial, and electric vehicle industry demands.

Facility Expansion at a Glance

| Feature | Details |

|---|---|

| Existing Headquarters | Approximately 70,000 sq. ft. (production and warehouse combined) |

| Newly Leased Facility | 30,000 sq. ft. in Sparks, Nevada |

| Additional Under-Construction Space | Over 90,000 sq. ft. in upcoming development |

| Key Operations | CNC machining, sheet metal fabrication, tube laser cutting, welding, powder coating, and assembly |

Advanced Manufacturing Technologies and Their Impact

As industries evolve, the shift toward digital and automated manufacturing processes becomes increasingly apparent. Future Form Manufacturing’s capabilities underscore this evolution, as they integrate cutting-edge technologies like large-scale CNC machining, innovative laser cutting systems, and automated welding processes. The enhanced machinery and equipment not only raise production efficiency but also contribute to reducing the nerve-racking amounts of rework and quality control issues that often trouble manufacturers.

Companies are under constant pressure to manage your way through the little details of production while maintaining rigorous standards. By investing in advanced equipment, manufacturers are better equipped to meet the ever-growing expectations around precision engineering, high throughput, and cost-effectiveness.

High-Precision Technologies in Manufacturing

One significant component of this technological transformation is the focus on precision. High-precision manufacturing is key to sectors like aerospace and medical industries, where even slight mistakes can lead to severe consequences. Here are some of the critical aspects that make high-precision manufacturing super important:

- CNC Machining: Offers consistent and repeatable production, ensuring every piece meets strict tolerances.

- Laser Cutting: Enables highly precise cuts, improving both product quality and aesthetic appeal.

- Tube Laser Cutting: Allows for complex geometries and tight tolerances, which are essential for specialized applications.

- Automated Welding Processes: Enhances production speed while reducing human error and workplace risks.

A New Era in Industrial Manufacturing Trends

The transformation to Future Form Manufacturing is an opportune moment to take a closer look at the broader trends enveloping the manufacturing landscape. With a focus on digital integration, precision engineering, and facility expansions, the industry is witnessing a convergence of technological advancements and business growth strategies that signal promising shifts for the future.

These trends reflect a clear commitment to not only staying competitive but also offering products and services that are reliable, efficient, and of premium quality. Industry experts suggest that the company’s strategy to triple production capacity could set a new benchmark in the manufacturing scene, especially in the high-stakes areas of defense, energy, transportation, and medical equipment production.

Market Drivers and Key Influences

Several major factors are shaping the current manufacturing environment. Understanding these drivers can help companies find your way through the tangled issues and tricky parts of today’s market. Some of these key market drivers include:

- Technological Innovations: The rapid adoption of automation and robotics is revolutionizing production processes.

- Global Economic Trends: Shifts in global markets can have significant impacts on supply chain costs and material availability.

- Policy and Regulation: Changes in business tax laws and environmental policies require strategic adaptation and thorough oversight.

- Consumer Demand: With a growing emphasis on quality and customization, manufacturers must refine their production processes to secure customer satisfaction.

- Competition: Intense competition in both domestic and international markets pushes companies to innovate and streamline operations continually.

Opportunities Presented by the Rebranding Initiative

Future Form Manufacturing’s rebranding is more than a cosmetic change—it’s a strategic repositioning with numerous benefits. This change sends a clear message to stakeholders that the company is serious about growth, innovation, and staying ahead in a fast-paced digital world. The rebrand creates a platform for new product development, expanded market reach, and renewed investor confidence.

In this evolving landscape, companies must figure a path through challenging bits and subtle parts of the manufacturing process while addressing supply chain constraints and potential market disruptions. Rebranding can be seen in this context as part of a broader strategy to manage your way through overhauling operational frameworks and improving strategic communications.

Strategic Advantages of a Fresh Brand Identity

Here are some of the strategic advantages that come with a deliberate and well-executed rebranding initiative in the manufacturing sector:

- Enhanced Market Recognition: A new, modern identity can catch the eye of both old and new customers, fostering stronger brand loyalty.

- Future-Focused Image: By aligning the brand with innovation and technology, companies signal that they are ready for tomorrow’s challenges today.

- Investor Confidence: A refreshed brand often attracts fresh capital, which is critical when investing in the sophisticated machinery and infrastructure upgrades that modern manufacturing demands.

- Cultural Renewal: Internally, a rebrand can serve as a rallying call, inspiring staff to embrace change and drive performance improvements.

Diving Deep into the Digital Transformation of Manufacturing

One of the most significant trends influencing manufacturers today is the digital transformation of production processes. With the increasing adoption of data analytics, automation, and even artificial intelligence (AI), manufacturers are now better equipped to handle the complicated pieces of production with greater ease and precision. As Future Form Manufacturing invests in new technology, it exemplifies a broader industry trend where digital tools help companies work through the fine points of production without compromising quality.

Digital transformation in manufacturing brings new ways to manage your path through quality control, inventory management, and even workforce training. Companies can now leverage advanced software to monitor operations in real time, reducing the nerve-racking chances of errors and ensuring that production stays on track.

Key Digital Tools Reshaping Production Processes

The integration of digital tools into manufacturing processes is creating more efficient and responsive production environments. Below are some of the digital tools and techniques that are leading this revolution:

- Data Analytics: Enables manufacturers to sift through vast arrays of data to identify trends, improve production methods, and enhance overall operational efficiency.

- Automation Software: Helps in managing robotic systems which can operate 24/7, ensuring consistency and easing the burden on human operators.

- Remote Monitoring Systems: Allow management to keep a close eye on various production lines in real time, quickly addressing any deviations from expected performance.

- Predictive Maintenance Tools: Use AI-driven insights to predict when equipment may fail, thus saving time and reducing costly downtimes.

- Digital Twin Technology: Offers a virtual replica of physical systems, enabling engineers to simulate production scenarios and optimize steps before applying changes in the real world.

Implications for the Data Center, Medical, Defense, Energy, and Transportation Sectors

Future Form Manufacturing’s expansion coincides with rising demands in critical industries such as data centers, healthcare, defense, energy, and automotive sectors. Each of these sectors relies heavily on precision engineering and robust manufacturing capabilities, which are directly supported by modern production technologies and sufficient production capacity.

For example, in the data center industry, precision-engineered components ensure that servers and cooling systems operate at peak efficiency. In the medical field, the manufacturing of precise instruments and devices demands a level of quality assurance that advanced machining and assembly processes can provide. Similarly, defense and energy sectors require parts that meet strict regulatory standards and can withstand the most off-putting conditions under combat or operational stress.

How Expanded Capacities Impact Industry Sectors

Below is an overview of how the rebranding and expansion efforts by Future Form Manufacturing can benefit these critical sectors:

- Data Centers: Greater production capacity enables faster turnaround of custom enclosures, cooling systems, and mounting solutions necessary for scaling data operations.

- Medical Equipment: Enhanced precision and rapid prototyping capabilities ensure that surgical instruments and diagnostic devices meet the exacting standards of medical practices.

- Defense: High-precision manufacturing processes deliver parts that must meet rigorous testing and compliance standards, ensuring security and reliability under extreme conditions.

- Energy: With growing investments in renewable and traditional energy sources, reliable manufacturing of complex components is key to building resilient energy infrastructures.

- Transportation: Automotive and electric vehicle sectors rely on high-quality fabrication for everything from chassis components to intricate ornamental details, which modern manufacturing technologies can deliver with minimal errors.

Managing the Tricky Parts of Modern Manufacturing

The shifting landscape of industrial manufacturing involves dealing with several tricky parts and tangled issues. One of the super important aspects of this change is the need to make your way through numerous challenges—ranging from supply chain delays to quality control hurdles. As the industry moves toward increased automation and digital tools, the ability to manage these challenges with innovative solutions becomes the key to maintaining competitiveness.

Future Form Manufacturing stands out by not only expanding its production facilities but also by providing robust support throughout the manufacturing process. From precision sheet metal fabrication to advanced welding and powder coating, the company’s collaborative approach helps mitigate many of the nerve-racking issues that can arise during production.

Common Challenges and How to Address Them

Below is a list of common production challenges and strategies for effectively handling them:

- Supply Chain Interruptions:

- Develop diversified supplier networks.

- Implement robust inventory management systems.

- Quality Control Issues:

- Invest in high-precision technology and automation.

- Use real-time monitoring and data analytics to spot trends.

- Workforce Training:

- Create ongoing skill development programs.

- Adopt simulation and digital twin technologies for training purposes.

- Technological Integration:

- Choose scalable automation solutions.

- Ensure robust cybersecurity measures are in place.

Exploring Economic Impacts and Business Tax Considerations

As companies like Future Form Manufacturing expand their operations, there are significant economic implications to consider. With more than 100,000 square feet of production and warehouse space now in play—and even more impending—the company is well-poised to influence local economic growth. This growth includes job creation, increased tax revenues, and greater investment in local infrastructure.

Moreover, modern manufacturing expansions can have a ripple effect on the broader supply chain and ancillary industries, including automotive and electric vehicles, where rapid innovations are changing the rules of engagement. When a manufacturer scales up, it often prompts a host of related changes in procurement, logistics, and even business tax laws. These subtle details can significantly affect overall profitability and operational efficiency.

Economic Benefits and Considerations

Some of the economic advantages associated with expanded manufacturing operations include:

- Job Creation: Facility expansion typically leads to additional hiring, which benefits the local economy.

- Increased Tax Revenues: More robust operations contribute to higher local tax incomes, which can support community development projects.

- Supply Chain Growth: Expanded production often necessitates more comprehensive supply chain networks, benefiting other businesses in the region.

- Research and Development Incentives: Larger-scale operations may attract government or private R&D funding, fostering future innovations.

Given these factors, it is key for both policymakers and corporate leaders to dig into actionable strategies that not only boost production but also ensure compliance with evolving business tax regulations and economic frameworks.

Impacts on Employee Retention and Workforce Development

While much attention is paid to the tangible aspects of expansion—such as facility size and production capabilities—there is a significant human component as well. Employee retention and workforce development are critical, especially in a sector that is sometimes riddled with tension over rapid automation and evolving roles.

Future Form Manufacturing’s rebranding and expansion efforts are not isolated from these human considerations. Modern manufacturing environments increasingly require workers to have advanced technical skills and the flexibility to adapt to new production methods. Training programs, upskilling initiatives, and strategic employee engagement models are becoming common themes in discussions about successful expansions.

Strategies for Workforce Advancement

Companies looking to manage your way through the subtle parts of employee retention and workforce development can consider several strategies, including:

- Skills Training Programs:

- Offer regular training sessions on new technologies and machinery.

- Provide certifications that encourage continuous learning and professional growth.

- Employee Engagement Initiatives:

- Conduct regular feedback sessions to understand the concerns and suggestions of the workforce.

- Promote team-building events that foster camaraderie and a shared commitment to quality.

- Career Development Paths:

- Develop clear career trajectories for employees within the company.

- Encourage mentorship programs that pair experienced workers with newer team members.

Marketing and Branding in a Competitive Landscape

In today’s multichannel marketing environment, rebranding efforts have to support not just operational changes but also marketing communications. The new identity of Future Form Manufacturing must resonate with both current clients and potential new partners, ensuring that the refreshed brand image aligns with the company’s advanced capabilities and modernized production processes.

Marketing in the industrial manufacturing sector can be tricky. It requires a balanced approach that highlights both the technical prowess of the production process and the reliability of the finished products. In this delicate balance, companies must find your way through the fine points of brand messaging while addressing the tangible benefits of their expanded operations.

Tactics for Effective Industrial Marketing

Successful marketing strategies in the manufacturing sphere often involve:

- Digital Marketing Campaigns:

- Implement targeted advertising to reach specific segments such as energy, defense, and medical sectors.

- Utilize analytics to measure engagement and refine marketing strategies over time.

- Content Marketing:

- Produce opinion editorials, case studies, and technical white papers that demonstrate expertise.

- Leverage social media platforms and podcasts to bring focus to innovations and industry trends.

- Interactive Digital Editions:

- Offer comprehensive digital resources (e.g., e-newsletters and digital magazine editions) to keep stakeholders informed.

- Ensure easy accessibility so that clients can remain engaged with the brand from anywhere.

Environmental Considerations and Sustainable Manufacturing

While Future Form Manufacturing’s expansion is primarily focused on increasing capacity and enhancing product quality, it also presents an opportunity to address broader environmental concerns. The adoption of more energy-efficient technologies and environmentally friendly practices is becoming super important in the modern era. Sustainable manufacturing not only meets regulatory compliance but also aligns with growing consumer expectations around corporate responsibility.

Manufacturers now find themselves working through additional layers of considerations regarding energy consumption, waste management, and resource efficiency. By using state-of-the-art equipment and lean manufacturing principles, companies can mitigate their environmental footprint while still delivering high-quality products.

Sustainable Practices in Modern Manufacturing

Key sustainable practices that are gaining prominence include:

- Energy-Efficient Equipment:

- Adopting machinery with lower power consumption rates.

- Utilizing smart sensors to optimize energy usage during production cycles.

- Waste Reduction Programs:

- Implementing recycling initiatives for scrap material and off-cuts.

- Employing methods to repurpose excess materials and reduce overall waste.

- Lean Manufacturing Techniques:

- Streamlining production processes to minimize overproduction.

- Improving inventory management to reduce resource waste.

- Environmental Certifications:

- Pursuing environmental quality certifications to highlight commitment to green practices.

Integrating Automation and Human Ingenuity

The modern manufacturing landscape is a blend of cutting-edge technology and the irreplaceable human touch. Automation may help steer through many of the complicated pieces of production, but there will always be a need for creative problem-solving and decision-making—the kind only humans can offer. Future Form Manufacturing’s strategy incorporates both automated systems and skillful human intervention, ensuring that while operations are efficient, they remain flexible and adaptive.

In practical terms, this dual approach reduces the intimidating aspects of relying solely on machinery, instead offering a well-rounded system where technology and human expertise complement each other. This balanced integration helps companies not only produce higher-quality products but also foster an environment where innovation is encouraged and maintained.

Advantages of a Hybrid Workforce

Employing both automation and a skilled workforce offers numerous benefits, such as:

- Increased Efficiency: Automation handles repetitive and data-intensive tasks, freeing up human workers to focus on strategic initiatives.

- Improved Quality Control: Combining real-time data monitoring with human inspection reduces the chance of overlooking minor but crucial quality issues.

- Enhanced Flexibility: Humans can better adapt and respond to unexpected issues or changing production needs.

- Boosted Morale: Workers who are engaged in meaningful tasks rather than monotonous processes tend to feel more valued and motivated.

Industry Outlook and Future Trends

The industrial manufacturing sector is set to continue its transformation in the coming years. Trends such as Industry 4.0, smart factories, and increased digitalization are shaping a future where manufacturers must constantly find your way through the labyrinth of new technology and rapidly shifting market demands. Future Form Manufacturing’s comprehensive expansion and rebranding efforts position it as a key player ready to meet these challenges head-on.

Analysts predict that such expansions will have ripple effects across various sectors, from automotive to healthcare, and even to electric vehicles. With a focus on higher production capacities, advanced automation, and sustainable practices, the future promises innovation that is as exciting as it is essential.

Emerging Trends to Watch

Looking ahead, several emerging trends are worth noting:

- Integration of Artificial Intelligence: AI will increasingly be used to help get into the subtle parts of quality control, predictive maintenance, and customer demand forecasting.

- Digital Twin Technology: By creating virtual representations of physical systems, manufacturers can simulate and refine production processes with minimal risk.

- Increased Customization: Mass customization is expected to become standard practice as customers demand more tailored products.

- Energy and Sustainability Focus: As environmental concerns grow, manufacturers will need to adopt greener practices and sustainable energy solutions.

- Global Supply Chain Integration: Companies are likely to invest more in technologies that make finding your path through intricate global supply chains more manageable.

Conclusion: Charting a Clear Path Forward

The rebranding of B&J Industries as Future Form Manufacturing and its significant facility expansion in Nevada are a testament to a forward-thinking approach in industrial manufacturing. In a world filled with confusing bits and off-putting challenges, the company’s robust strategy showcases how to work through the tangled issues of modern production while staying true to quality and innovation.

By investing in key technologies, expanding operational capacities, and rethinking the very way they present themselves to the world, Future Form Manufacturing is setting a new standard for what is possible in the industry. The move represents a calculated effort to merge technological advancements with human ingenuity, ensuring that the company remains competitive in sectors ranging from energy and defense to data centers and electric vehicles.

As the business and economic landscapes continue to evolve, the strategic rebrand and the bold expansion serve as a reminder of the importance of staying adaptable and proactive. With its enhanced capabilities and forward-thinking approach, Future Form Manufacturing is well-positioned to meet the challenges of the modern marketplace while steering through the tricky parts of both technology integration and workforce transformation.

In summary, the journey from B&J Industries to Future Form Manufacturing is not just a change in name—it’s a comprehensive reimagining of how manufacturing can and should evolve in the digital age. Through large-scale facility expansion, state-of-the-art technology adoption, and a thoughtful approach to human resource development, the future of manufacturing looks both innovative and sustainable.

As industry professionals and enthusiasts alike take a closer look, the lessons drawn from this transformation are clear. Companies that dare to rebrand and expand, while remaining rooted in quality and forward-thinking principles, will likely emerge as leaders in the new era of manufacturing. The debate is over—innovation, modernization, and a willingness to manage your way through the nerve-racking challenges of the current landscape are not optional; they are essential.

Ultimately, the path forward involves an unwavering commitment to continuous improvement, strategic reinvestment, and an openness to change. Whether you are part of a small business, an industrial manufacturing giant, or even a data center operator, the future will belong to those who can balance modern technology with sound human judgment and agile business strategies.

It is in this spirit of optimism and calculated risk that Future Form Manufacturing embarks on this new chapter, inviting collaboration, creativity, and sustained success. As markets continue to evolve and new challenges emerge, the company’s evolution serves as a powerful reminder that innovation is not a destination—it’s a journey. And with every new technological advance and every expanded production line, we are witnessing the birth of a future that is as bright as it is promising.

With this transformation, the broader industrial community is encouraged to take a closer look at their own practices, ensuring that they figure a path through the subtle details and tricky parts of production. By embracing change and harnessing the power of digital tools, modern manufacturers everywhere can learn from Future Form Manufacturing’s bold steps and renew their commitment to excellence in the manufacturing arena.

As we look forward to new breakthroughs and industry advancements, one critical takeaway remains: the power of rebranding and facility expansion can rejuvenate a company’s outlook, ignite further innovation, and ultimately create a legacy that stands as a testament to both tradition and transformation in the ever-evolving world of industrial manufacturing.

Originally Post From https://www.thefabricator.com/thefabricator/news/shopmanagement/bj-industries-rebrands-as-future-form-manufacturing-expands-in-nevada

Read more about this topic at

Rebrand fuels growth: REBEL scales up Kannapolis, RoCo …

Washington-Based Chain Continues Fuel Rebranding