Diverse Welding Careers in an Evolving Economy

The recent Georgia Trade School job fair in Acworth, Ga., has provided a striking window into the colorful world of modern welding careers. Far beyond the standard image of a welder in a workshop, the event showcased an industry filled with creative flair, ever-evolving technology, and unexpected career twists. For many professionals in metal fabrication, opportunities now extend into fields that blend artistry with technical precision, a shift that has stirred both excitement and caution among employers and workers alike.

In today’s environment, where economic pressures and international trade uncertainties continue to cast a long shadow, the welding industry is managing its way through tricky parts and tangled issues that were once relegated to purely technical debates. Instead, these discussions now intertwine with broader topics like marketing savvy, evolving technology, and even creative design projects.

Creative Custom Fabrication: From Pirate Ships to Whimsical Deciduous Trees

At the heart of the job fair, one could not help but notice the stunning blend of art and engineering represented by the custom fabrication projects on display. One of the showstoppers was a project involving a pirate ship—yes, a pirate ship—designed with an aluminum subframe and clad in plywood for a dinner show venue. Far from your typical structure, this project highlights how fabricators are now embracing creative and even theatrical challenges.

Another creative twist comes in the form of a welded deciduous tree slated to be approximately 55 feet tall, complete with a canopy incorporating a treehouse. This installation, destined for a new corporate center, embodies the spirit of innovation and boundary-pushing design. These projects, with their quirky subject matter and unexpected design elements, reflect the industry’s move away from the predictable. Instead, metal fabricators are now expected to blend traditional structural integrity with imaginative, almost story-like craftsmanship.

Opportunities in Inspection and Non-Destructive Examination (NDE)

The job fair did not only highlight creative fabrication efforts. In one corner, representatives from companies specializing in non-destructive examination (NDE) painted a picture of an industry that is increasingly reliant on advanced inspection systems. These systems, which include innovative inspection tools that “crawl” the sides of large structures, demonstrate that welding and fabrication are no longer only about bringing metal pieces together—they are also about ensuring the reliability and safety of heavy-duty installations.

Working through these sophisticated inspection methods has its own set of tricky parts and confusing bits—a mix of technological intrigue and practical application. As companies such as Applied Technical Services explained, careers in NDE are not only about using high-tech tools but also about having an eye for the small distinctions and fine shades that determine a weld’s quality. For prospective welders, these roles are both intimidating and inspiring, setting a standard that merges safety with innovation.

Specialized Fabrication in Modern Industries

From shipbuilding to industrial furniture design, the array of industries represented at the job fair has never been more diverse. One company, for instance, showcased its capabilities in creating custom fabrication designs for Atlanta’s burgeoning film sector. By exploring fabrication that reaches into both entertainment and practical utility, companies like ID3 Group prove that their expertise stretches far beyond standard truck frames or pressure vessels.

This diversification has significant implications for metal fabricators, who must now figure a path through a landscape that demands adaptability. The industry—historically grounded in well-known construction methods and traditional projects—now finds itself flooded with projects that emphasize both aesthetic appeal and unconventional design elements. Whether it’s designing industrial pieces for movie sets or creating metal sculptures for upscale corporate spaces, the new generation of fabricators is expected to embrace both the hard, physical labor and the creative, subtle details that make each project unique.

A Shift in Industry Perception Amid Economic Uncertainty

The job fair also served as a response to a relatively slow summer in the welding sector, a slowdown that many attributed to the nerve-racking uncertainties surrounding tariffs and trade policies. Yet, within this context, industry leaders are beginning to see the potential in reimagining the traditional roles of welders and fabricators.

Rather than simply taking on the standard welding assignment, many companies are now actively developing projects that require the workforce to figure a path through not only physical challenges but also the metaphorical twists and turns that come with economic shifts. Employers find that the best welders are not just skilled in their craft but are also keenly aware of the subtle parts and little details that elevate a project from the ordinary to the exceptional.

Transitioning from Technical Skill to Marketing Savvy

One of the most compelling narratives from the job fair came from Jonny Herrera, a pipe welder whose journey from the Kentucky Welding Institute to becoming the founder of the clothing brand Pearlsnap Pimps truly underscores the evolution of career roles within the welding industry. Herrera’s story is a testament to how fully embracing both the technical and the creative aspects of the trade can lead to unconventional pathways of success.

Initially, Herrera’s commitment to perfecting the craft was evident from his 16-hour days and his willingness to stay back to practice—even if it meant recording social media videos. His approach to the craft wasn’t just about handling the heavy metals; it was about capturing every single twist and turn, every fine point of the work, and turning that skill into a distinct personal brand.

This blending of technical mastery with marketing insights is increasingly critical in today’s job market, where social media is as much a part of professional life as traditional networking. For many welders and fabricators, there is now a growing expectation to not only be experts in the shop but also to have an online presence that highlights their personal brand and the unique aspects of their work.

Exploring the Importance of Trade Schools in a Changing Landscape

Trade schools like Georgia Trade School are playing a pivotal role in preparing the next generation of welders to face both the nerve-racking and exhilarating parts of the industry. With job fairs that bring together a diverse range of companies, these institutions are not only teaching the craft but are also fostering an environment that encourages creative thinking and adaptation to new trends.

Such educational settings are crucial for helping students steer through the little details and hidden complexities of modern welding. The opportunity to interact directly with experienced professionals from various sectors provides students with invaluable insights into both the technical and marketing aspects of the trade.

Moreover, by hosting one of the largest job fairs in recent memory, Georgia Trade School has acted as a bridge between emerging talent and industry leaders. This networking helps upcoming welders understand that despite the intimidating technologies and off-putting economic uncertainties, there is a thriving demand for skilled professionals who can weave both tradition and innovation into their work.

Adapting to New Economic Realities in Metal Fabrication

The economic landscape in which today’s metal fabricators operate is as challenging as it is dynamic. With tariffs, shifting trade policies, and periodic economic slowdowns, companies are forced to figure a path through a maze of financial concerns. Yet, it is precisely these challenges that provide an opportunity for growth and innovation within the industry.

One of the most super important lessons emerging from recent industry events is that adaptability is key. Rather than being held back by nerve-racking market conditions, fabricators and their employers are learning to make their way through these challenges by embracing unconventional projects and diversified career roles.

By investing in training and staying abreast of technological advancements — like robotic automation and advanced inspection systems — companies are restructuring their processes to accommodate both cost pressures and the need for creative solutions. This is a striking reminder that in a world loaded with issues, the ability to reframe challenges as opportunities is a must-have skill for any business in metal fabrication.

The Increasing Role of Automation and Robotics in Welding

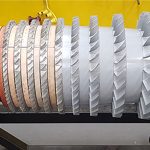

Modern advancements in automation and robotics have steadily started to change the face of welding. While some might see these technological advances as a threat to traditional craftsmanship, the reality is much more nuanced. Robots are now used to perform repetitive, painstaking tasks, enabling human workers to focus on the creative parts and fine shades that require a personal touch.

In many companies, automation supports the labor force by taking over the more nerve-racking repetitive tasks, thereby allowing welders to concentrate on projects that require nuanced expertise and a keen eye for detail. This trend illustrates a broader evolution within the industry: technology is not replacing the human element, but rather enhancing the industry by handling the tangled issues that are best left to machines.

Industry analysts suggest that working through these technological changes will require both a shift in mindset and ongoing education for workers. For instance, operators now need to figure a path through the integration process, which often involves dealing with confusing bits of software and understanding the subtle parts of machine operation.

Bridging Traditional Skills and Modern Demands

The current era of metal fabrication stands at the crossroads of traditional skills and innovative design. Many veterans in the field recall a time when welding was viewed as a straightforward trade—a matter of joining metals with measured precision. Today, however, the role of a welder is more complex. Professionals are now expected to integrate marketing savvy with technical skills, all the while figuring a path through the practical challenges of advanced design.

This bridging of old and new is evident in the job fair’s diverse representation. On one hand, there were clearly established companies specializing in non-destructive examination and heavy industrial fabrication. On the other hand, there were creative outfits that turned everyday welding projects into pieces of performance art or novel architectural installations. This dramatic shift isn’t just a temporary phase—it is a lasting change that reflects the industry’s response to modern challenges and opportunities.

For veteran welders, learning to manage your way through these new, subtle details may feel overwhelming at first. However, those who have embraced these changes have found that the rewards are great. An industry once defined by its rugged physical demands is now also defined by intelligent, creative approaches that combine hands-on skill with forward-thinking strategies.

Industry Insights: Making Sense of the Unexpected

Events like the Georgia Trade School job fair serve as a microcosm of larger industry trends. They show how the welding sector is not just surviving economic pressures but is also actively evolving to meet them. From small-scale, custom fabrication to large-scale automation projects, the industry is busy working through its many tricky parts and hidden complexities.

For instance, the participation of companies involved in high-tech inspection systems and creative design projects offers a glimpse into an industry that is smartly adapting its workforce to new demands. The event highlighted that the best welders are now expected to focus not only on the practical, tangible aspects of metal joining but also on the finer points that make their work unique—be it through the aesthetic appeal of a custom project or the inclusion of modern technology in routine procedures.

This paradigm shift is also drawing attention to the critical importance of continuous learning and collaboration, as professionals across various niches in metal fabrication emphasize the need to mentor younger workers and pass down the knowledge of both traditional techniques and modern practices. It’s a balancing act: preserving the heritage of the craft while making your way through the rapidly shifting demands of modern industry.

Advice for Aspiring Welders: Blending Craftsmanship and Modern Marketing

For those new to the field or considering a career in welding, the lessons from the job fair are illuminating. The experience underscores the value of both technical expertise and a dynamic personal brand—a combination that is becoming increasingly essential in the modern marketplace.

Here are some key takeaways for aspiring welders and fabricators:

- Embrace Diverse Opportunities: From industrial fabrication to creating spectacular custom pieces, recognize that there are endless possibilities waiting for those who can blend hard skills with creative vision.

- Keep Learning: With the integration of advanced technologies like automation and robotics, continuous education is critical. Keeping up with new systems and methodologies is not just an advantage—it’s necessary for survival.

- Develop Your Brand: As demonstrated by Jonny Herrera’s success with Pearlsnap Pimps, having a strong personal brand supported by social media can open unexpected career doors. Don’t be afraid to invest time in both honing your craft and sharing your progress online.

- Network Actively: Events like job fairs and trade shows are not only opportunities to showcase your skills but also platforms to meet industry veterans and peers who can offer valuable insights.

- Stay Flexible and Open-Minded: The industry is ever-changing. Being prepared to tackle unexpected projects—like designing a pirate ship or a towering deciduous tree—can set you apart from others.

These bullet points provide just a glimpse into the shifting priorities in metal fabrication. For all the aspiring welders out there, understanding that the field is full of both practical challenges and creative opportunities is the first step to carving out a successful career.

The Role of Trade Fairs in Fostering Industry Collaboration

Trade fairs, like the one hosted by Georgia Trade School, play an essential role in bridging the gap between traditional fabrication practices and modern industry expectations. They provide a platform where industry leaders, academic institutions, and emerging talents come together to share ideas, tackle tangled issues, and trade tips on best practices.

For many companies, these events are a valuable opportunity to showcase their latest technology, discuss the subtle parts of their design philosophy, and get real-time feedback from a diverse audience. With the integration of advanced inspection systems, automation, and creative fabrication, companies are not only demonstrating their products but are also revealing the fine points of a transformation that touches every level of the industry.

The collaboration fostered at these gatherings is proving to be a game changer. Employers have been able to assess firsthand the wide range of skills that modern welders bring to their roles—from traditional craftsmanship to the ability to operate complex machinery. It’s an environment where the old and the new meet, and where every participant gets a chance to figure a path through future challenges.

Overcoming Economic and Technological Challenges in Metal Fabrication

For many in the metal fabrication field, economic headwinds and technological advancements can feel like overwhelming obstacles. However, the recent job fair proved that these challenges also bring opportunities. Companies are learning to work through the tangled issues of modern trade policies and tech integration by investing in both human talent and state-of-the-art equipment.

The industry’s approach has shifted from simply managing problems to embracing a culture of innovation and continuous improvement. For example, despite tariffs and trade uncertainties, companies are finding that the best way to succeed is to remain agile—constantly retooling their operations to meet evolving customer demands and market trends.

Here’s how many fabricators are approaching these economic and technical hurdles:

- Diversification: Expanding into creative projects and non-traditional fabrication roles to balance economic slowdowns.

- Investment in Technology: Leveraging automation, robotics, and advanced inspection systems to improve productivity and safety.

- Continuous Staff Training: Equipping employees with the skills to handle both traditional welding and new technological tools.

- Collaborative Partnerships: Engaging with educational institutions like Georgia Trade School to cultivate fresh talent and promote innovation.

This strategic mix of creative problem solving and technological investment indicates that metal fabricators are not only surviving in the current economic environment—they are thriving in it by finding innovative ways to work through the confusing bits of modern business.

Looking to the Future: Trends and Predictions for the Welding Industry

As the industry moves further into the 21st century, several key trends are likely to shape its future. First, the integration of automation and robotics in welding processes will continue to grow. These technologies, which help reduce the more overwhelming and nerve-racking repetitive tasks, will allow human talent to focus on the subtle details and creative challenges that machines simply cannot replicate.

Second, there is a rising emphasis on personalization and targeted advertising not just for finished fabrications, but also for marketing professional services. With social media playing an increasingly important role in career development, welders who combine technical expertise with a strong personal brand are likely to enjoy a competitive advantage.

Third, ongoing economic uncertainty will continue to push companies to diversify their offerings. Instead of relying solely on traditional manufacturing, many organizations are expanding their scope to include custom designs and one-of-a-kind installations. In a market that’s full of problems and loaded with issues, the ability to adapt and tailor services to niche markets is a key competitive edge.

Finally, education and continuous training will remain fundamental. With trade schools and industry conferences serving as hubs of learning and collaboration, future welders will be well-prepared to tackle both the tricky parts of day-to-day operations and the more subtle differences that separate good work from great work.

Final Thoughts: A New Era for Welding and Fabrication

The Georgia Trade School job fair provided a compelling snapshot of where the welding and fabrication industry is headed. With projects ranging from whimsical pirate ships to innovative industrial installations, it is clear that today’s metal fabricators are reimagining their roles in a way that combines age-old craftsmanship with modern technology and creative vision.

While challenges remain—whether they are economic twists and turns, the intimidating nature of new inspection technologies, or the nerve-racking implications of shifting trade policies—the industry’s response has been one of adaptability and resourcefulness. For welders and fabricators old and new, the road ahead is full of opportunities if they are willing to work through the twisted and tangled issues of today’s market.

Ultimately, the job fair served as a reminder that in an industry defined by both its hard edges and its creative possibilities, there is no single, straightforward path to success. Instead, the future belongs to those who can blend traditional skills with modern marketing savvy, who are not afraid to dive in and figure a path through both the challenging bits and the creative twists of metal fabrication.

As the welding industry continues to expand into new territories—technologically, financially, and creatively—it is essential for everyone involved to stay flexible, continuously learn, and remain open to innovative ideas. Each new project, whether it’s a fantastical pirate ship, a towering deciduous tree, or a state-of-the-art robotic inspection system, represents an opportunity to push past the intimidating and complicated pieces of the past and craft a future that is as bright as it is bold.

For industry leaders, educators, and emerging talent alike, the message is clear: embrace the change, tackle the hidden complexities, and let creativity and hard work pave the way forward. By doing so, the welding and metal fabrication industry can continue to innovate, thrive, and set new standards for excellence in the face of ever-evolving challenges.

Originally Post From https://www.thefabricator.com/thefabricator/blog/arcwelding/georgia-trade-school-job-fair-highlights-the-range-of-welding-careers

Read more about this topic at

Diverse Welding Opportunities: From Oil Rigs to Art Installations

Choosing the Right Industry as a Welder